The Ins and Outs of Barcode Label Printing

The Ins and Outs of Barcode Label Printing

As a business owner, you know the importance of efficiency in all aspects of your operation. One area that may not get as much attention, but is crucial for accurate inventory management and seamless customer service, is barcode label printing.

In this article, we’ll explain what a thermal label printer is, the different types of barcode labels available, and provide tips for maximising efficiency in barcode label printing. Specifically, we’ll explore the differences between ladder and picket fence style barcode labels and how to choose the right one for your business needs.

The Importance of Barcode Label Printing

Barcode label printing is a critical aspect of managing inventory, sales, and shipping in a business. Barcode labels provide a unique identifier for each product, making it easier to track inventory levels, manage sales, and fulfill orders. Without an accurate inventory management system, businesses run the risk of over or understocking products, leading to lost revenue or unhappy customers. Barcode label printing is also crucial for tracking shipping progress, allowing packages to be tracked from origin to destination.

What is a Thermal Label Printer?

A thermal label printer is a type of printer that uses heat to print text and images onto paper or synthetic label materials. Thermal printers are ideal for barcode label printing because they produce high-quality, durable labels quickly and efficiently. There are two types of thermal label printers: direct thermal and thermal transfer. Direct thermal printers use heat to produce an image directly onto the label material, while thermal transfer printers transfer ink onto the label material using a thermal ribbon.

Types of Barcode Labels

There are several types of barcode labels available, including paper, polyester, and polypropylene labels. The type of label you choose will depend on the application and environment in which it will be used. For example, paper labels are suitable for indoor use in dry environments, while polyester labels are more durable and can withstand exposure to moisture and chemicals. Polypropylene labels are ideal for outdoor use and can withstand exposure to extreme temperatures and weather conditions.

Ladder Style vs Picket Fence Style Barcode Labels

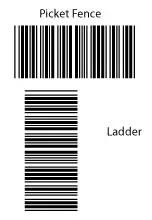

Ladder style and picket fence style barcode labels are two of the most common types of barcode labels. Ladder style labels have vertical bars, or “ladders,” between each barcode, while picket fence style labels have horizontal bars, or “pickets,” between each barcode. The choice between ladder style and picket fence style labels depends on the application and the type of barcode scanner being used.

Ladder style labels are ideal for high-speed scanning applications because the vertical bars make it easier for scanners to read the barcode quickly. Picket fence style labels are better suited for applications that require scanning from multiple angles because the horizontal bars provide more contrast, making it easier for the scanner to read the barcode.

Choosing the Right Barcode Label for Your Business

Choosing the right barcode label for your business needs involves considering several factors, including the application, environment, and type of scanner being used. If you’re unsure which label to choose, consult with a barcode label printing expert who can help you select the best option for your business needs.

How to Maximise Efficiency in Barcode Label Printing

Maximising efficiency in barcode label printing starts with selecting the right label and printer for your needs. Once you have the right equipment, there are several tips you can follow to ensure efficient label printing.

First, make sure your printer is properly calibrated for the label material you’re using. This will ensure that the labels print correctly and reduce the risk of wasted materials. Second, use high-quality barcode label maker software to design and print your labels. This will help ensure that the labels are accurate and easy to scan. Finally, consider investing in a barcode label printer for shipping to streamline your shipping process and reduce the time it takes to fulfill orders.

Tips for Using a Thermal Label Printer

In addition to choosing the right label and barcode label design software, there are several tips you can follow to get the most out of your thermal label printer. First, keep your printer clean and free of debris to prevent jams and ensure accurate label printing. Second, regularly replace the printhead and other parts as needed to ensure the printer is functioning at its best. Finally, make sure you have a backup printer on hand in case of a malfunction or breakdown.

Top Thermal Label Printers for Barcode Label Printing

There are many thermal label printers on the market, but some are better suited for barcode label printing than others. Some of the top thermal label printers for barcode label printing include:

- Zebra GX430t

- TSC DA320 (Desktop)

- TSC MB340T (Commercial / Industrial)

Barcode Label Maker Software

Barcode label maker software is essential for designing and printing accurate, scannable barcode labels. Some of the top barcode label maker software options include:

Barcode Label Printer Maintenance Tips

To ensure your barcode label printer is functioning at its best, it’s important to perform regular maintenance. This includes cleaning the printer, replacing parts as needed, and keeping the printer software up to date. Consult the manufacturer’s instructions for specific maintenance tips and recommendations.

Barcode label printing is a critical aspect of managing inventory, sales, and shipping in a business. Choosing the right label and printer for your needs and following best practices for efficient label printing can help increase accuracy, reduce waste, and save time. By understanding the differences between ladder style and picket fence style barcode labels and selecting the right label for your application, you can ensure that your business is running at peak efficiency.