Welcome to Labelling Secrets #60

In this Edition:

- VIP Color VP600 VP700 VP750 trade in and consumables credit - February 2020

- Bonus Offers on the TSC TX600 Label Printer - February 2020

- Label Printer training, Service and Maintenance

- The Difference between Narrow and Wide Edge Leading (NEL vs WEL)

$500+GST Trade in and $500 consumable credit on purchase of VIPCOLOR Printers in Feb

Label Power Has a Super Special Offer to Get You Up and Printing in 2020!

We will give you $500+GST trade in on any of your working colour label printers AND a $500 account credit for blank labels or consumables when you purchase any of the following printer models in February 2020: VP600, VP700 or VP750.

<link product id vip-color-vp600-colour-label-printer-high-performance>VIPColor VP600

Engineered for high performance label printing, yet priced within the reach of most small-medium enterprises. Manufacturers who are struggling today, with high pre-printed label costs and wastage linked with their wide product offerings, will find the VP600 a must-have printer.

- Super High Quality Memjet Label Printing in a Compact Format

- Now with Bigger Individual 200ml CMYK Ink Cartridges

- Rent this printer from only $59 per week plus GST!

The VP700 enables high impact, color labels up to 8.5 inches wide at a print speed of 6 ips or 12 inches per second (30 or 60 feet per minute) and with print resolutions of 1600 x 1600 dpi or 1600 x 800 dpi, respectively. The VP700 is perfect for printing on-demand and Just In Time (JIT) labeling requirements in manufacturing or logistic environments. The VP700 is also ideal for custom or private brand labeling needs and provides unprecedented flexibility and convenience to any company that owns one.

- Super Fast, High Quality Memjet Label Printing

<link product id vip-color-vp750-colour-water-resistant-label-printer>VIPColor VP750

The VP750 is the next generation of digital print-on-demand colour label printers with Enhanced Water Resistance Printing Technology*.

Building on the proven technology of our VP700, it utilises Enhanced Water Resistance Printing Technology that produces vibrant, coloured, waterproof labels. The result is great looking colour labels that are suitable for Chilled Food & Beverage, Animal Care, Cleaning products, Chemicals, Pharmaceutical products and most moisture exposed products.

- New Water Resistant Memjet Inks for Beer, Wine and Juice Labels

*Compatible with synthetic and paper based labels. However, users are advised to conduct their own tests for compatibility prior to mass production.

Offer Valid Until February 28th, 2020

TSC TX600 Special Bonus Offers for January/February

Start 2020 with a Brand New TSC TX600 and Get the Following Bonuses:

- Free External Label Unwinder (Valued at $75)

- 12 Month Hot Swap Guarantee - If the Printer has any Service-Related Issues in the Next 12 Months, Label Power will Swap the Printer with a Brand New TX600 (Printhead Excluded)

- Free Shipping to major cities in Australia and New Zealand

Features of the TSC TX600 Include:

- 600 DPI - Allows for the Printing a Very Small Characters with Fine-Edged Fonts

- Includes Serial Port, Internal Ethernet and USB/USB 2.0 Connectors - Allows for Very Easy Installation

- Colour LCD Screen - Allows for Easy Management of the Printer Settings

- Ribbon Capacity up to 300m (984 ft) - Print More Labels per Ribbon

The TX600 thermal transfer desktop barcode printers, with LCD display, supports more printing applications than any other printer in its class. TX600 600 dpi printer featuring precise calibration and registration required for printing the smallest labels.

Offer Valid Until February 28th, 2020

Service and Repairs Available for Thermal Transfer Label Printers, Rewinders and Unwinders in Brisbane, Sydney and Melbourne.

Service and repairs are available for Zebra, Honeywell, TSC, Datamax-O'Neil, VIP Color, Epson, Primera, OKI, Evolis and Intermec thermal transfer label printers. LabelMate dispensers and rewinders and label applicators.

Label Power have the following colour and thermal printer servicing and training options:

Popular options include:

- Return to Base* Servicing/Repair, Includes 1 Hour Labour (Sending Machine to Label Power)

* consumables and spare parts are charged extra

^ additional return freight charges may apply

Or

- 60 Minute On Site Training, Servicing/Repair or Installation

* Remote locations may incur extra travel charges

Or

- 1 Hour Remote Training or Support

Remote training and support carried out via phone and/or online via Team Viewer www.teamviewer.com.au

Contact us with your request/s

The Difference Between Narrow and Wide Edge Leading (NEL vs WEL)

It is essential to quote the correct direction and position so that your labels are produced and applied correctly.

An important and common term within the labelling industry is NEL and WEL, which stand for Narrow Edge Leading and Wide Edge Leading. This can be a confusing term for someone who isn't familiar with the labelling industry, although it simply suggests which edge of the label comes off the roll first.

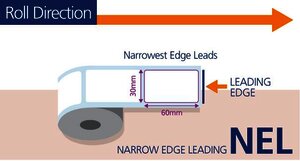

NEL (Narrow Edge Leading)

This means that the shortest edge of the label will come off the label roll first, meaning it is narrow edge leading. In the diagram above, it is a 60mm by 30mm label, so the shortest side is the 30mm side, so that means that the 30mm side will be leading.

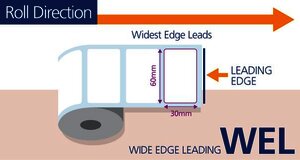

WEL (Wide Edge Leading)

This means that the widest edge of the label will come off the label roll first, meaning it is wide edge leading. In the diagram above, it is a 60mm by 30mm label, so the widest side is the 60mm side, so that means that the 60mm side will be leading.

The diagram above demonstrates how the labels will come out on the roll. Normally, the label is quoted using the width first (60mm) followed by the length (30mm).

NEL and WEL figures out which direction your label will be when produced, although that is not everything when it comes to the outcome of a label. There is also the roll direction itself, which is the detailed position/rotation a label can be put on a roll in any of 8 directions, depending on whether the label is wound inside the roll or exposed on the outside.

You can read about roll direction here. If you are unsure about whether you need a narrow edge lead or a wide edge lead, give us a call and speak to one of our friendly and helpful staff here who will be happy to assist you.

We encourage all customers to visit our website to find information about our products and contact us on 07 3710 7000 or sales@labelpower.com.au

PS: Label Power are THE SOURCE for all popular labelling software including Seagull Scientific Bartender, Teklynx Nice Label, Easylabel, Nice Label and More.