Rough vs Smooth: Choosing the Right Tactile Finish for Your Label with Spot Gloss

Introduction to Tactile Finishes for Labels

Label designers and marketers are always looking for ways to make their designs stand out but when it comes to labels it’s quite a specific skill. There’s so many ways to add variety within the label itself – with clever design-work and some clever printing.

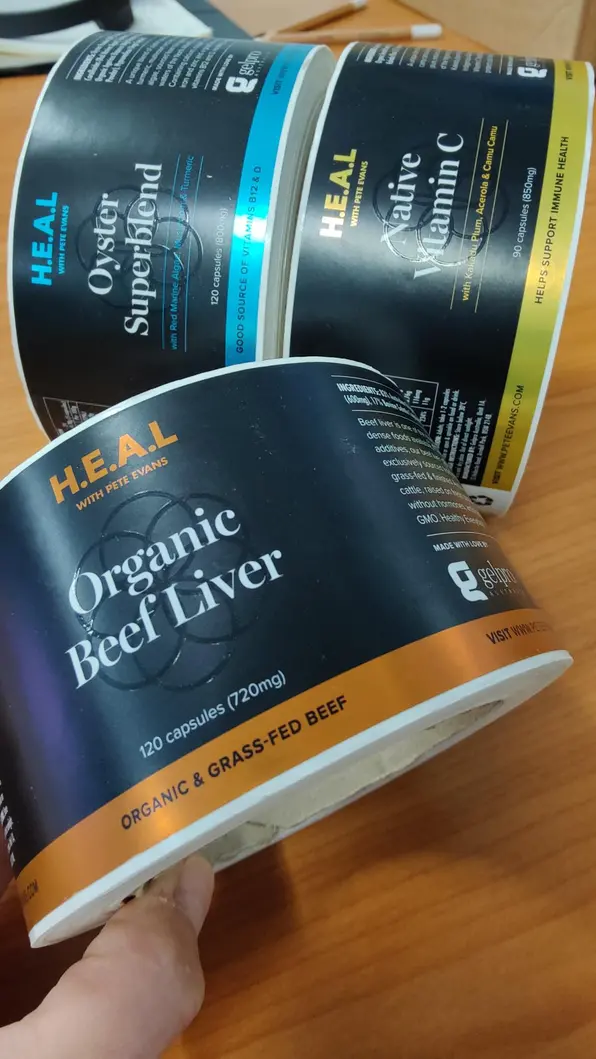

One way to achieve a striking label design is by using tactile finishes. Tactile finishes add a unique texture to labels that not only makes them visually appealing but also enhances the overall experience for the consumer. In this article, we will discuss the benefits of using spot gloss varnish, how it compares to other finishes, and how to incorporate it into your label design.

Tactile finishes are applied to labels to add a unique texture that can be felt by the consumer. These finishes can range from rough to smooth depending on the desired effect. Some common tactile finishes include embossing, debossing, and foil stamping. Each of these finishes adds a different texture to the label, creating a unique look and feel.

Understanding Spot Gloss, Spot Varnish, and Spot UV Coating

Spot gloss, spot varnish, and spot UV coating are all terms used to describe the same finishing technique. This technique involves applying a glossy coating to specific areas of the label, rather than the entire label. The result is a label with a subtle shine that draws attention to specific areas of the design.

What is Spot UV?

Spot UV is a finishing technique that involves applying a clear gloss coating to specific areas of the label. This coating is then cured with ultraviolet light, creating a durable and long-lasting finish. Spot UV can be applied to both paper and plastic labels, making it a versatile finish.

Advantages of Using Spot Gloss Varnish

One of the main advantages of using spot gloss varnish is that it adds a unique texture to the label that can be felt by the consumer. This texture enhances the overall experience for the consumer, making the label more memorable. Spot gloss varnish also draws attention to specific areas of the design, making it an effective way to highlight important information or features.

Another advantage of using spot gloss varnish is that it is a cost-effective way to enhance the label design. Unlike other tactile finishes such as embossing or foil stamping, spot gloss varnish can be applied to specific areas of the label, reducing the overall cost of the finishing process.

Comparing Spot Gloss vs Metallic Finish

While spot gloss varnish adds a subtle shine to the label, metallic finishes add a more dramatic effect. Metallic finishes use metallic foils to create a metallic effect on the label. These finishes are available in a wide range of colors, including gold, silver, and bronze.

The main difference between spot gloss and metallic finishes is the level of shine. Metallic finishes create a high shine, while spot gloss creates a subtle shine. Additionally, metallic finishes are more expensive than spot gloss varnish, making them less cost-effective for some label designs.

Spot Gloss Varnish vs Other Finishes

When choosing a tactile finish for your label design, it is important to consider the advantages and disadvantages of each finish. Spot gloss varnish is a cost-effective way to add a unique texture to your label design. However, other finishes such as embossing and foil stamping can add a more dramatic effect to your label design.

Embossing creates a raised texture on the label, adding depth and dimension to the design. Foil stamping adds a metallic or holographic effect to the label, creating a high-end look and feel. While these finishes are more expensive than spot gloss varnish, they can add a significant impact to your label design.

Ask our team for a Design Consult with one of our labelling experts.

Label Power has recently implemented a 1000 gigabyte internet connection which means we can host a Design Consult video conference meeting or printer demonstration online. Clients can access this solution using Zoom, Skype, WhatsApp and Microsoft Teams.

We can review your existing label design to determine if there are more cost-effective manufacturing and printing options or improved design options.

Supporting Australian Manufacturers

Many organisations are now learning that the potential cost savings achieved, via using overseas manufacturers, does not necessarily translate to maintaining their business continuity due to the recent issues with shipping and production, so now is the time to support the Australian manufacturers who create jobs for local residents and support the local economy.